针对各种颗粒状的原料,根据用户产品的工艺需求、称重的精度要求、厂房设备布局等,联塑机器为客户提供整套定制化的自动化工厂完整方案,从原材料的储存、物料输送、称重混料、除湿干燥、自动分配输送至各机台生产。

多场景应用介绍

储料:原材料储存可选择吨包投料方式或人工开包投料,通过气力输送至料仓

称重混配:针对需要混配的多种材料,采用“多组份称重式混料机”实现各种材料按预设配比进行精确计量,并进行充分混合,配比精度可达0.2%.

干燥系统:按生产工艺需求,混合材料通过气力输送至热风干燥机或除湿干燥机达到低露点要求(除湿干燥可达-50℃露点)

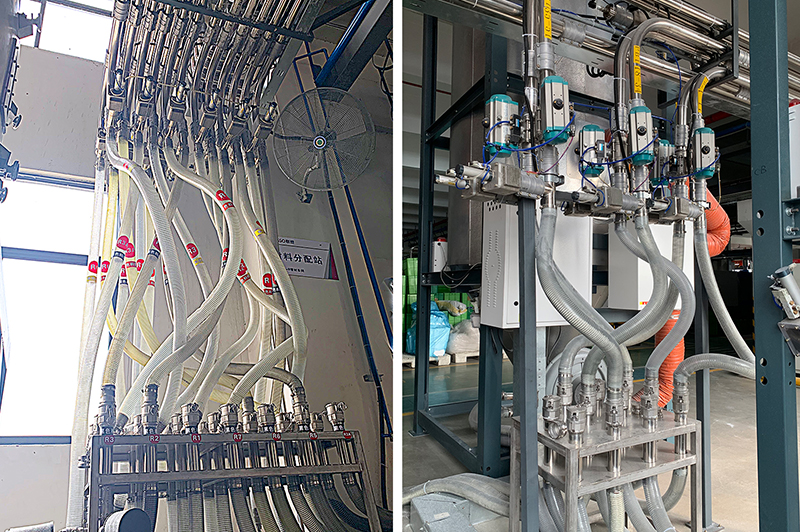

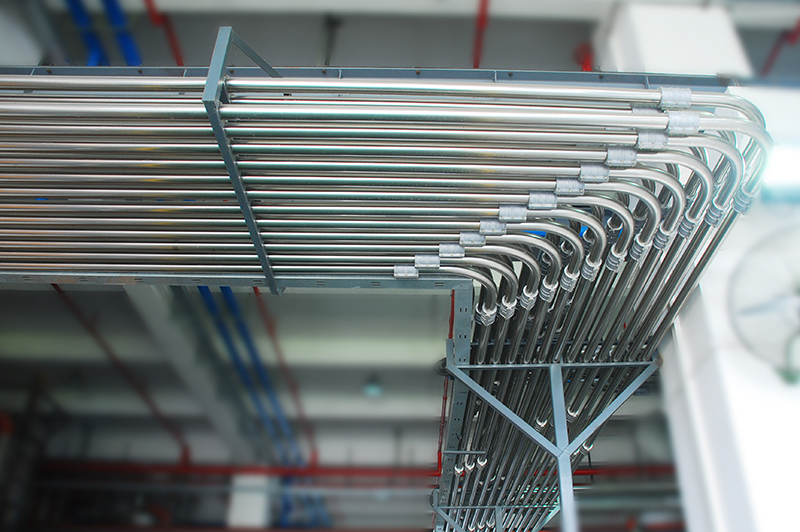

输送系统:干燥后的原料可通过“分配站”或“共用管道”负压输送到各机台上方的“真空吸料斗”,针对产品颜色多的产品也可选用“失重式色母机”在线混色。

现 场 施 工

联塑机器融合26年塑料设备制造经验,提供整套挤出/注塑上下游自动化系统方案,100%独立研发的集成控制系统, 熟悉塑料成型工艺流程,匹配最优的解决方案、全自动包装系统、生产数据采集分析系统的全生态整体解决方案。

目前海内外已完成塑料供料系统项目168个,覆盖设备超过2500台注塑机,项目从方案的制定、自制生产、现场施工、调试验收。实现解决新旧厂房改造、多配方、多颜色、高填充、远距离输送系统。